Description

? Negative Resist NR9-3000PY is a negative tone photoresist designed for 365 nm

wavelength exposure, using tools such as wafer steppers, scanning projection aligners,

proximity printers contact printers.

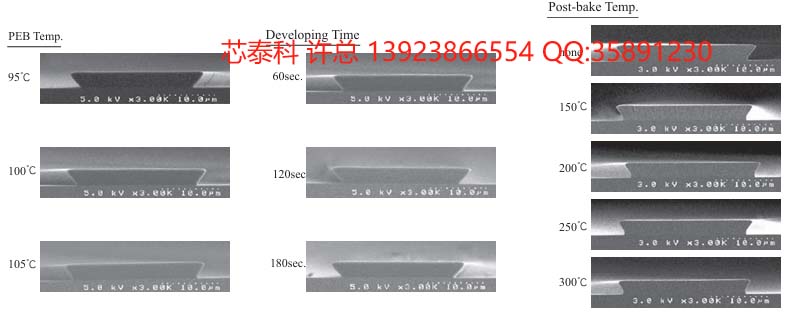

? After resist development NR9-3000PY exhibits a negative-sloping resist sidewall profile,

which facilitates a simple resist lift-off process.

? These are advantages of NR9-3000PY over other resists: - superior resolution capability - fast develop time - easy adjustment of the degree of resist undercut as a function of exposure energy - temperature resistance of up to 100°C - easy resist removal in Resist Remover RR2 or acetone - shelf life exceeding 3 years at room temperature storage.

? The formulation processing of NR9-3000PY were designed with regard to

occupational environmental safety. The principal solvent in NR9-3000PY is

cyclohexanone development of NR9-3000PY is accomplished in a basic water

solution.

Properties

? Solids content (%) 31-35

? Principal solvent cyclohexanone

? Appearance light yellow liquid

? Coating characteristic very uniform,

striation free

? Film thickness after 150°C hotplate bake for 60 s

Coating spin speed, 40 s spin (rpm): (nm)

800 5700-6300

3000 2850-3150

4000 2460-2720

5000 2140-2326

? Sensitivity at 365 nm exposure wavelength (mJ/cm2 for 1 μm thick film) 190

? Guaranteed shelf life at 25°C storage (years) 3

Processing

1. Application of resist by spin coating at ed spin speed for 40 s.

2. Begin dispensing Edge Bead Remover EBR2 simultaneously onto the top bottom

surfaces of the spinning, coated substrate through nozzles 0.5-1.0 cm the edge of

the substrate as soon as edge bead forms (3-5 s after ceasing resist dispense). Stop

dispensing EBR2 5 seconds prior to completion of spin coating cycle.

3. 150°C hotplate bake for 60 s. (softbake)

4. Resist exposure with a tool emitting 365 nm wavelength.

5. 100°C hotplate bake for 60 s. (post-exposure bake)

6. Resist development in Resist Developer RD6 by spray or immersion.

Development time for 3 μm thick film, for example, is 17 s.

7. Resist rinse in deionized water until water resistivity reaches prescribed limit.

8. Drying of resist.

9. Removal of resist in Resist Remover RR4 at 110°C or in acetone.

Note: The above procedure refers to substrates, which are good conductors of heat such as

silicon, GaAs etc. Bake times need to be increased by a factor of 3.5 for substrates that are

poor conductors of heat such as glass.

Hling Precautions

Negative Resist NR9-3000PY is a flammable liquid. Hle it with care. Keep it away

heat, sparks flames. Use adequate ventilation. It may be harmful if swallowed or touched.

Avoid contact with liquid, vapor or spray mist. Wear chemical goggles, rubber gloves

protective coating.